Manufacturing Solutions

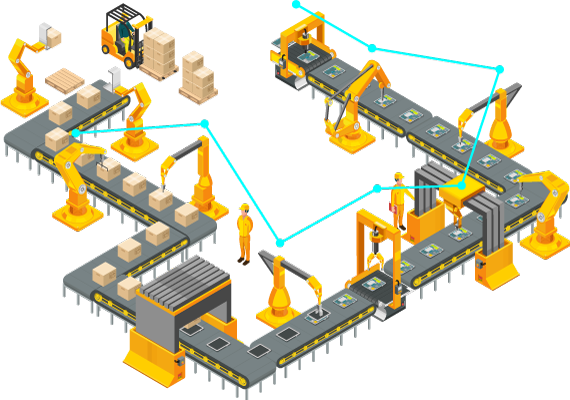

Network monitoring to avoid production slowdowns and prevent cyber risksIn manufacturing, time equals money

The integration of advanced manufacturing networks, high tech automation, and physical processes are some of the main elements characterizing the 4th industrial revolution, better known as the Industry 4.0 or the Industrial Internet of Things (IIoT). Consequently, manufacturing networks are more complex and highly heterogeneous, and most of the time operating with an increased risk of industrial specific vulnerabilities. Vulnerabilities like cyber and operational incidents, as shown by Norsk Hydro in 2019, several car manufacturers in 2017, and by hundreds of plant floors every day.

Whether it is a company with one plant or hundreds of factories worldwide, efficiency and excellence in the network infrastructures are key to maximize operational efforts and avoid bottlenecks & downtime, which in turn adds costs. And in manufacturing, time equals money. When a device, data center, or server on the network fails, accurate and fast troubleshooting is crucial. Every minute of downtime impacts business production, and so, profit.

More specifically for the manufacturing sector, the Operational Technology (OT) is the core technology, including any hardware and software that are used to sense and capture data as well as monitor and control the behavior of physical devices, processes, and events of the entire Industrial Control System (ICS). Typical OT networks are comprised of switches, monitors, sensors, valves, and manufacturing devices managed by an ICS system.

Some of the most difficult challenges associated with monitoring manufacturing IT and OT network infrastructure are:

- Achieving real-time network monitoring

- Detecting networking and operational issues before they cause downtime

- Preventing unplanned downtime due to equipment failure

- Remote access control

- Remote troubleshooting (intermittent) issues on hard to reach remote sites

- Managing cyber threats effectively

Visibility and control over OT and IT networks

Excellence in network monitoring infrastructures means anticipating an incident with augmented visibility and gaining full control of the environment for network administrators. How to do so?

Accessing the network traffic

Deploying network test access points (TAPs) throughout the Industrial Ethernet framework ensures safety, uptime, and improved efficiency. Installing TAPs for all monitoring feeds guarantees 100% of the network traffic is copied and transmitted to monitoring tools, achieving real-time network monitoring, and detecting operational issues before they cause downtime.

Managing & optimizing data flow

OT infrastructures within numerous locations must consider a visibility architecture utilizing both fiber and copper connectivity. Once the network access architecture is arranged, it is time to aggregate and monitor the network traffic before transmitting it to the analysis tools. However, due to the complexity and distribution of OT networks, speeds, the volume of data and traffic could be hard to manage. Network Packet Brokers (NPB) help bring the accessed traffic together and manage it, optimizing the performance of any monitoring and security tools across the entire IT and OT networks. How? By giving each tool the right packet data, thereby increasing network efficiency while reducing costs.

Data capture and analysis

To get a fast and reliable real-time overview of what is happening on the network, manufacturing industries require visibility and control over both OT and IT networks without impacting the integrity of the environment. The ideal solution is to have network traffic analysis tools that can be easily transported and deployed onsite but controlled remotely, for all the manufacturing industries with operations spread over multiple locations. This eliminates time-consuming and expensive onsite travels for IT and OT specialists, while still offering fast drill-down to the network issues. In case direct traffic access by an onsite technician is required, it is best to provide them with dedicated tools that offer quality traffic capture and timestamping, for a quick and reliable packet capture analysis.

Real-time network monitoring starts with high-quality infrastructures. Discover the Profitap portfolio, or request a quote for customized IT and OT network monitoring infrastructure solutions.

Industrial Network Visibility & Security with Profitap and SCADAfence

SCADAfence’s non-intrusive platform for deep packet inspection (DPI) together with Profitap’s network test access points (TAPs) and Network Packet Brokers (NPB) solutions, work together to bring network traffic visibility and asset inventory management in real-time and compliance to all OT & IoT industry regulations.

![]()